Trimmers and Deflashers

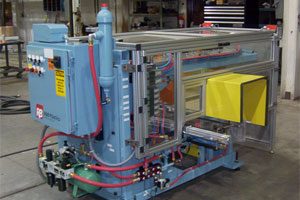

R&B Plastics Machinery offers turnkey trimming systems for plastic containers and parts. Our product lines feature stand-alone and line integrated machines for deflashing and final finish operations. Each machine is designed with modular bases, rugged construction, tight tolerances, space consideration and easy service access. All equipment is backed with the largest service staff in the industry.

R&B Plastics Machinery offers turnkey trimming systems for plastic containers and parts. Our product lines feature stand-alone and line integrated machines for deflashing and final finish operations. Each machine is designed with modular bases, rugged construction, tight tolerances, space consideration and easy service access. All equipment is backed with the largest service staff in the industry.

Deflash Machinery

Our deflash machines are designed for vertical and horizontal positioning of the container. Standard units for low and medium volume can straddle existing conveyors or stand-alone. High volume deflashing applications require a servo indexing system complete with a bottle reject. Customers can choose center distances to handle families of containers, bottle scrap locations and control systems. Stand-alone deflashing units feature a modular base and operating system for future machinery additions.

Our deflash machines are designed for vertical and horizontal positioning of the container. Standard units for low and medium volume can straddle existing conveyors or stand-alone. High volume deflashing applications require a servo indexing system complete with a bottle reject. Customers can choose center distances to handle families of containers, bottle scrap locations and control systems. Stand-alone deflashing units feature a modular base and operating system for future machinery additions.

Chipless Dome Cut, Facing and Reaming

Designed for vertical and horizontal positioning of the container. All units are stand-alone and designed with modular bases for fit with R&B Deflash Machinery. Single to multiple heads are determined for production line speeds. All machines are indexing (escapement and servo) and feature finish clamp assemblies to precisely hold containers for finish operations. All feed units are servo driven with mounting plates for chipless or precision cutter assemblies. Chipless dome cutting utilizes R&B hollow spindle cutter heads to knife cut excess plastic in a ring (no chips or particles) without spinning the container. Precision spindle box assemblies with R&B cutter tooling designs are available for facing and container I.D. finishing.

Designed for vertical and horizontal positioning of the container. All units are stand-alone and designed with modular bases for fit with R&B Deflash Machinery. Single to multiple heads are determined for production line speeds. All machines are indexing (escapement and servo) and feature finish clamp assemblies to precisely hold containers for finish operations. All feed units are servo driven with mounting plates for chipless or precision cutter assemblies. Chipless dome cutting utilizes R&B hollow spindle cutter heads to knife cut excess plastic in a ring (no chips or particles) without spinning the container. Precision spindle box assemblies with R&B cutter tooling designs are available for facing and container I.D. finishing.

Specialty Trimmer & Deflasher Designs

Specialty Trimmer & Deflasher Designs

Custom machinery for trimming and cutting applications can be determined by our design staff. Our long-term experience in developing part cutting machinery for metal and plastic will provide your company with a competitive advantage.

Key Features

- Vertical bottle deflashing

- Bottles stand up throughout trimming process

- Pneumatic Deflashing

- Facing / ID reaming at one station

- Dome cutting (Patented technology)

- Timing screw positions the bottles on pre-determined center distances

- Large range of bottle sizes and configurations

- Bottle throughput is based on bottle size and configuration

- Utilizes pneumatic stops and escapements for bottle control

- 2-up configuration capable of 60 bpm

- 3-up configuration capable of 90 bpm

- 4-up configuration capable of 120 bpm

- Modular fabricated steel base

- Operator control station with Allen-Bradley processor and controls

- Safety guards with electrical interlocks

- Left and right side scrap shoot diversion options

- Custom design and manufacturing capabilities available