R&B personnel fully reconditioned and modernized a used Sterling dual-head Accumulator Machine. Our Rebuild Group thoroughly inspects and evaluates the old blow molding machinery to determine required components, then develops a quote at the most economical cost. We provide a rebuild/upgrade proposal that details all services and parts required.

Bottom-line: Our customer can have a full or partially refurbished machine with substantial savings over the cost of going with a new machine.

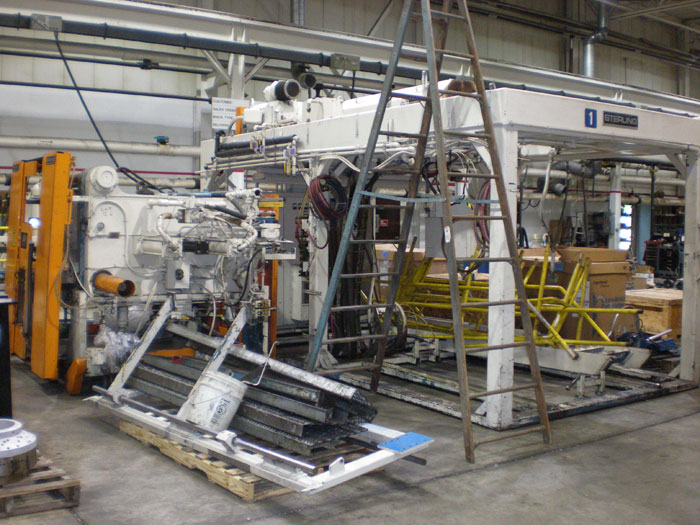

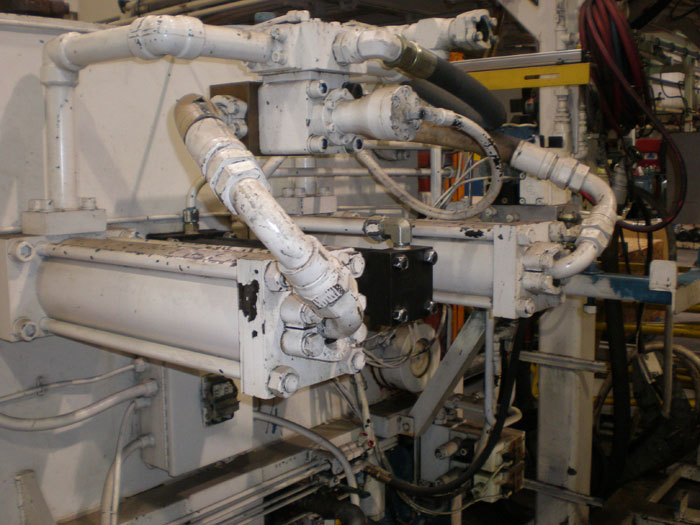

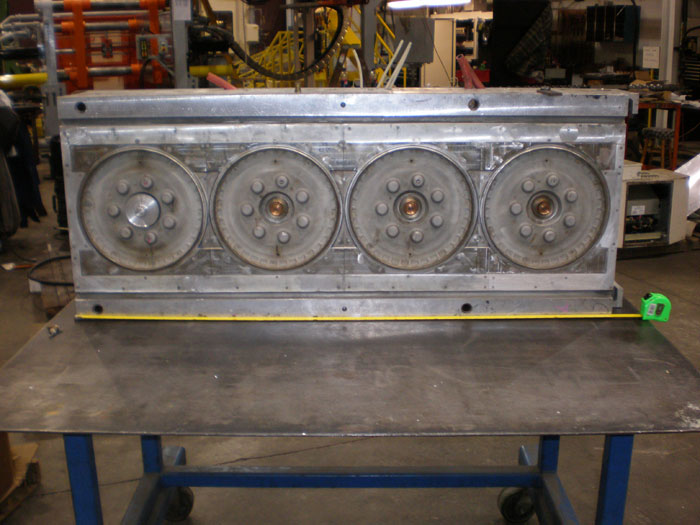

Before

- Excessive filth, surface areas are scratched, and paint is in poor condition

- Worn and damaged machine components

- Machine controls are outdated and difficult to readily locate replacement parts

- Machine safety components are outdated or missing altogether

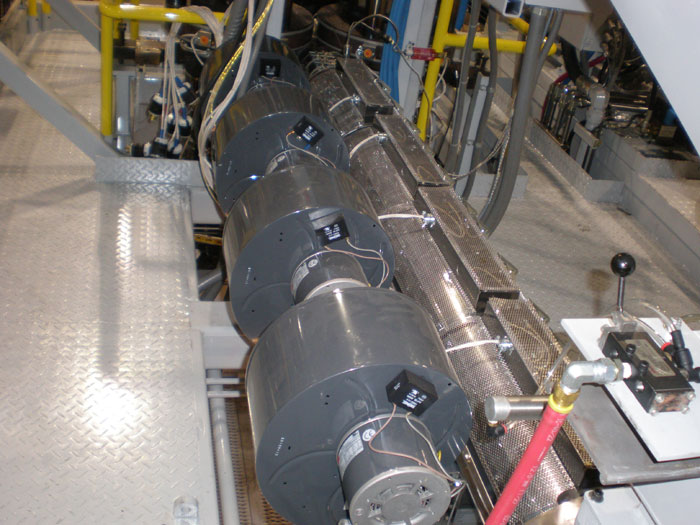

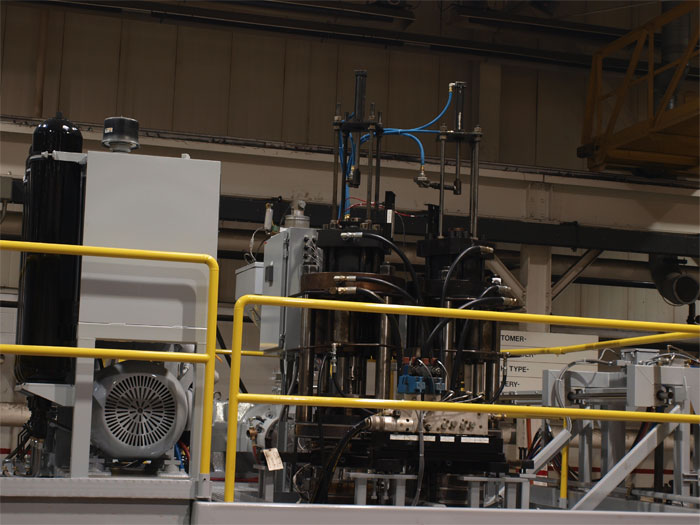

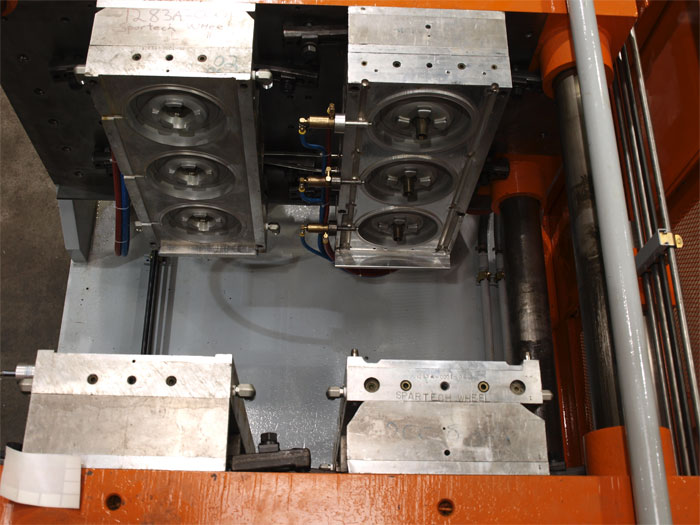

After

- Machine is sand blasted complete and then industrial primed and painted using electrostatic painting system.

- Complete teardown and replacement of worn or damaged components that meet or exceed OEM standards. Additionally, all R&B manufactured replacement components carry a one-year from ship date warranty.

- R&B machine controls are completely redesigned to the latest industry components and standards, including new PLC, HMI, recipe storage, and other automated-controls options.

- All R&B rebuilt machines are upgraded to the latest ANSI safety standards.

- Additionally, R&B can provide you with various automated take-out options.